Focused solutions for all aspects of lithium-ion battery manufacturing

Riken Keiki has been involved in the research and manufacture of lithium-ion batteries since the early stages of development. More than 10,000 units are in use at the production sites for lithium-ion batteries worldwide. RIKEN KEIKI continues to improve the safety of lithium-ion battery production through continuous improvement and integrates customers' needs into its products.

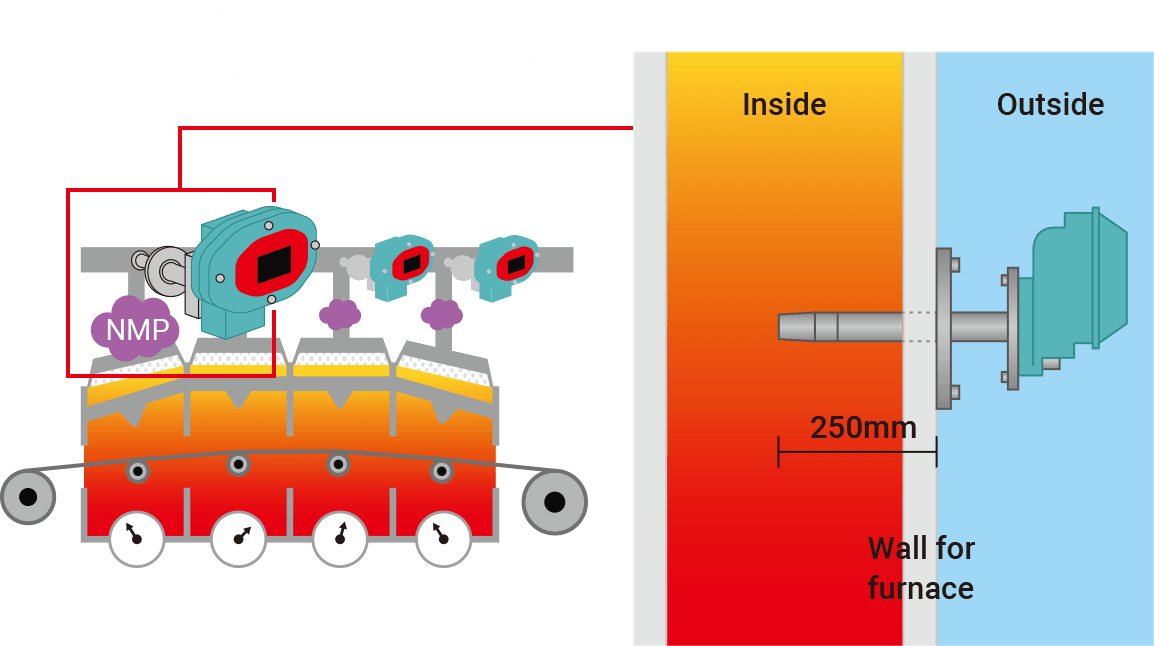

Gas monitoring for coating and drying processes

Highly heat-resistant in-line measurement.

Withstand operating temperatures up to 200 °C.

Ideal for coating and drying processes.

Measure the gas concentration exactly in the center of the exhaust duct.

The design with inline sensor (250 mm) allows conventional diffusion on the sensor without an additional pump.

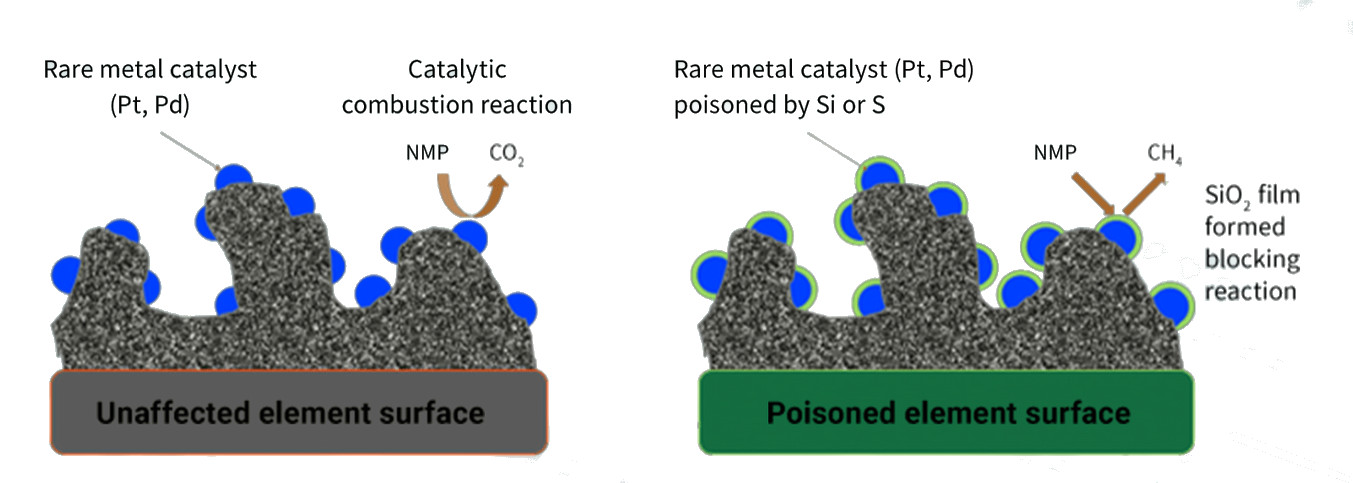

Silicon contamination

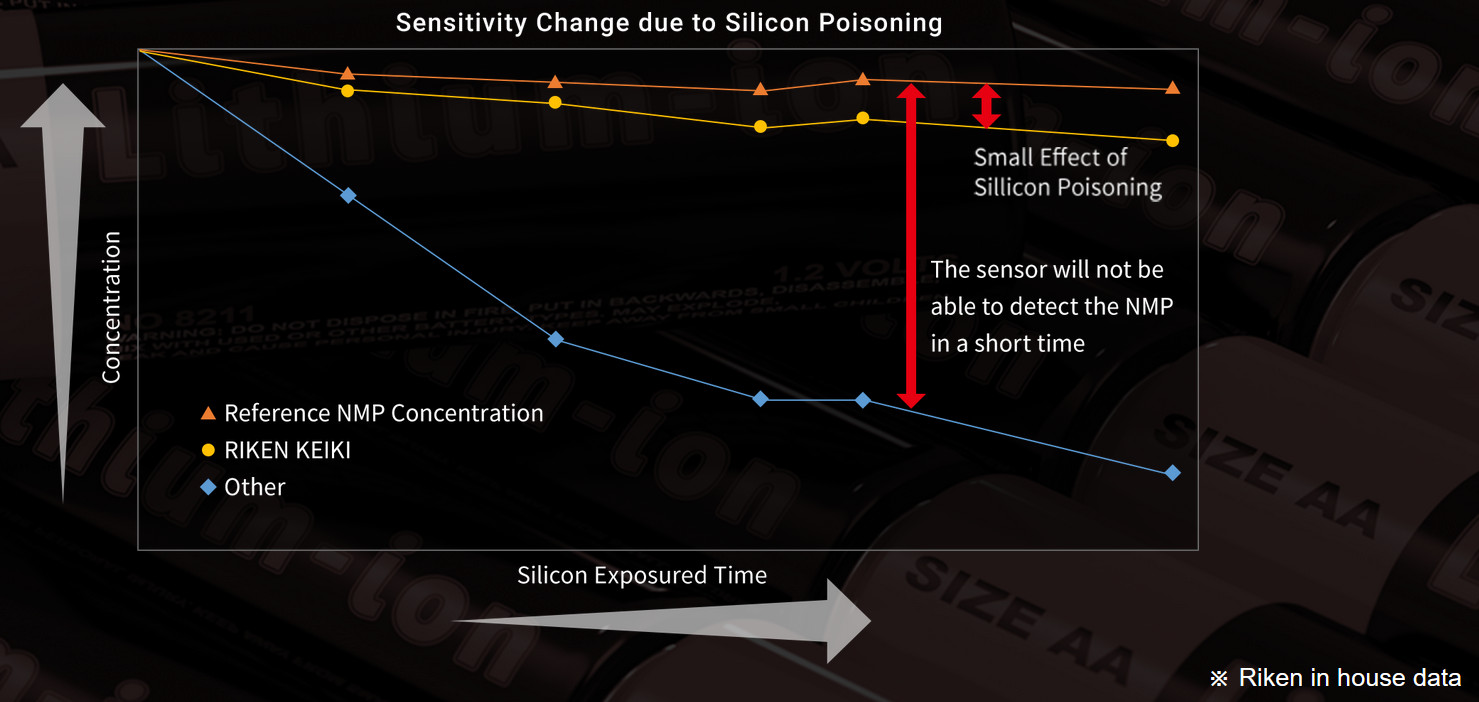

Ethanol is widely used as a calibration gas, which is relatively easy to obtain and handle. However, since ethanol has a low molecular weight, it will react with a "silicon-contaminated, damaged sensor". RIKEN KEIKI managed to suppress the deterioration to display the exact NMP gas concentration using a sensor calibrated to ethanol.

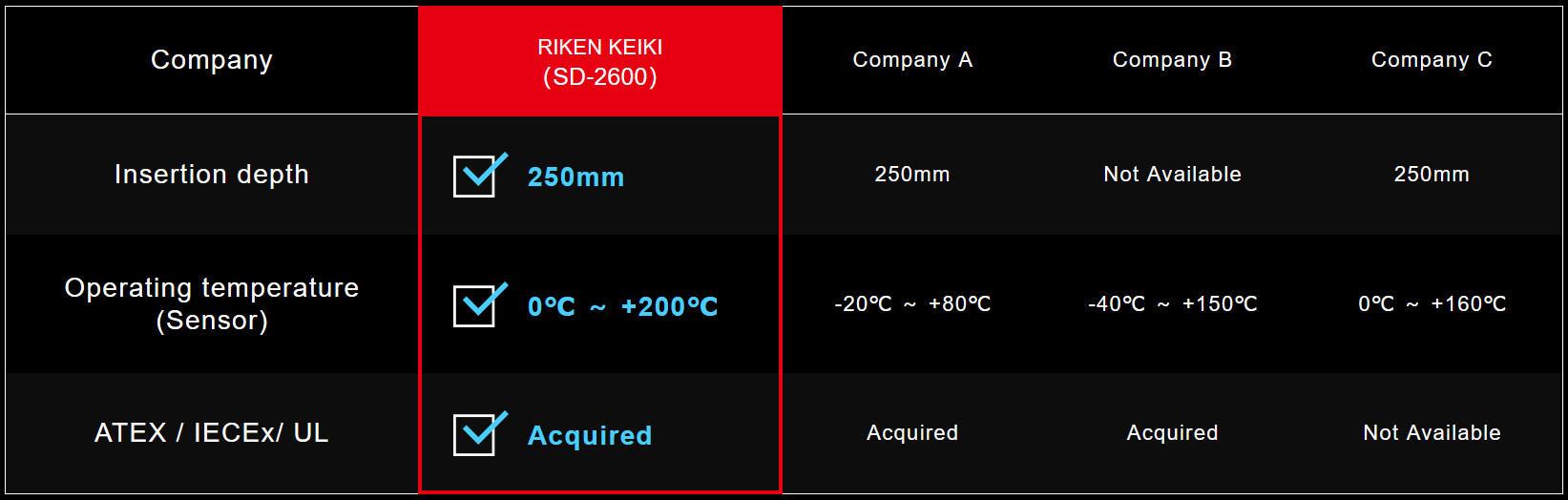

Device comparison to the Monitoring of combustible gases

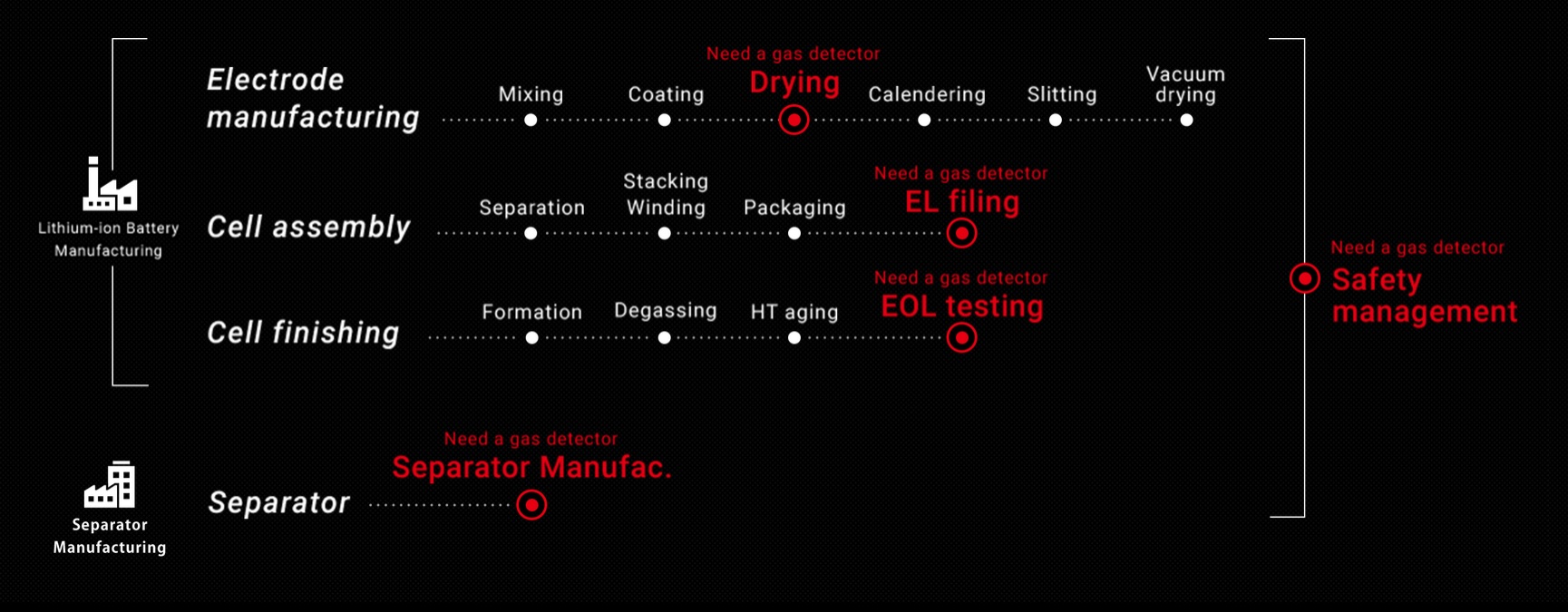

Importance of gas detection

______

Why is it important to detect gases in the production of lithium-ion batteries?

In the production of lithium-ion batteries, gases are used or generated in processes that can be flammable or toxic. Exceeding the allowable concentrations of these gases may pose a hazard to your personnel and equipment. Protect your employees and property by installing gas detectors designed for lithium-ion manufacturing applications.

Lithium-ion battery manufacturing process:

Electrode production - drying process

______

In the manufacture of electrodes for lithium-ion batteries, NMP is used as a solvent. NMP only evaporates at high temperatures during the drying process. As the NMP concentration increases, the risk of explosion increases. An ideal place for detecting NMP is the exhaust duct. By inserting the probe directly into the exhaust duct, NMP is detected in the middle of the duct and can withstand high temperatures and high concentrations.

RIKEN KEIKI products for drying processes

______

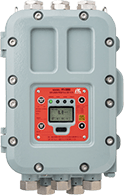

GD-A2400

Ex-proof

0°C ~ +160°C

SD-2500

Concentration display

Ex-Proof

0°C ~ +160°C

SD-2600

Concentration display

Ex-Proof

0°C ~ +260°C

SD-2700

Ex-proof

0°C ~ +250°C

Battery cell construction - electrolyte filling process

______

Gas detectors for electrolyte filling processes

______

SD-D58 (HW sensor)

Concentration indicator

Pump unit

Ex-proof

Cell Testing Process

______

Every lithium-ion battery must pass a test. During the evaluation test, flammable and toxic gases can be produced from the battery. Gas concentration monitoring is essential to prevent ignition and poisoning accidents during the testing process. When the gas detector detects the target gas, outside air must be sucked in from the inlet/outlet damper to reduce the gas concentration in the test equipment.

Gas detectors for the test process

______

GD-70D

Concentration indicator

Interchangeable sensor modules

Pump unit

Standard G1/4" screw-in connections

Manufacturing process for separators

______

Gas monitors for separator production processes

______

FI-900

Concentration display

Need external sampling unit

Ex-proof

Electrode Fabrication - Portable Gas Detectors for Personal Protection

______

s

Portable gas detectors

______

GADMS Lite

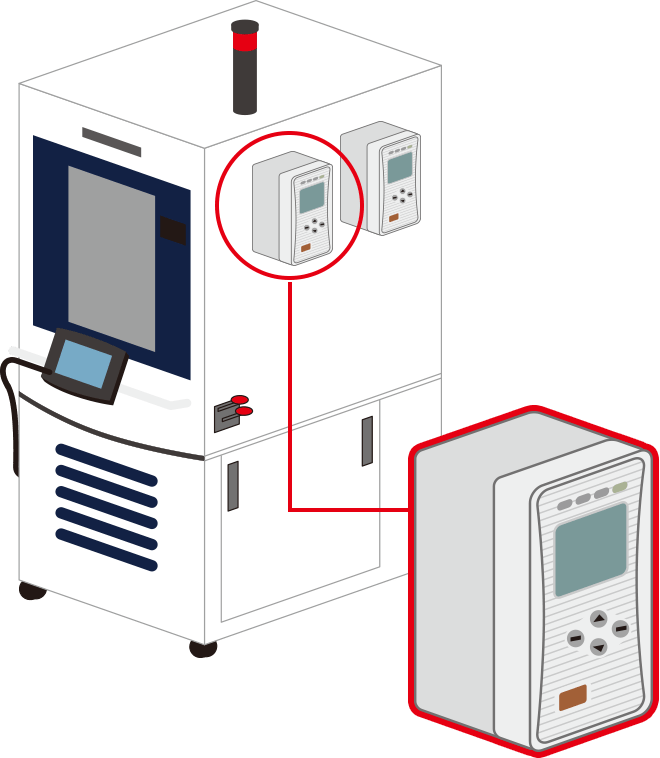

remote monitoring system

______

In addition to gas detectors, RIKEN KEIKI's original "GADMS Lite" system is also available for access to remote monitoring, configuration and alarm history via a PC, tablet or smartphone.