CombiSens multi-parameter platform for gas analysis

Multiparameter controller for analog and digital transmitters with extensive analyzer functions for Industry 4.0 - integration into a large number of fieldbus systems!

Imagine: You are looking for a gas analyzer that can determine several parameters of a gas or gas mixture. Cross-sensitivities or physical and chemical restrictions force you to discard various measuring principles. This results in a colorful mix of products from different manufacturers. That means that you have many devices, high space requirements, different operating concepts of the devices, many passwords and finally the time-consuming integration into your control with various interfaces that do not optimally fit your infrastructure.

We have developed a universal controller that is unique on the market. It combines the functions of a multi-parameter gas analyzer with the possibility of integrating almost any measuring principle and this completely independent of the manufacturer!

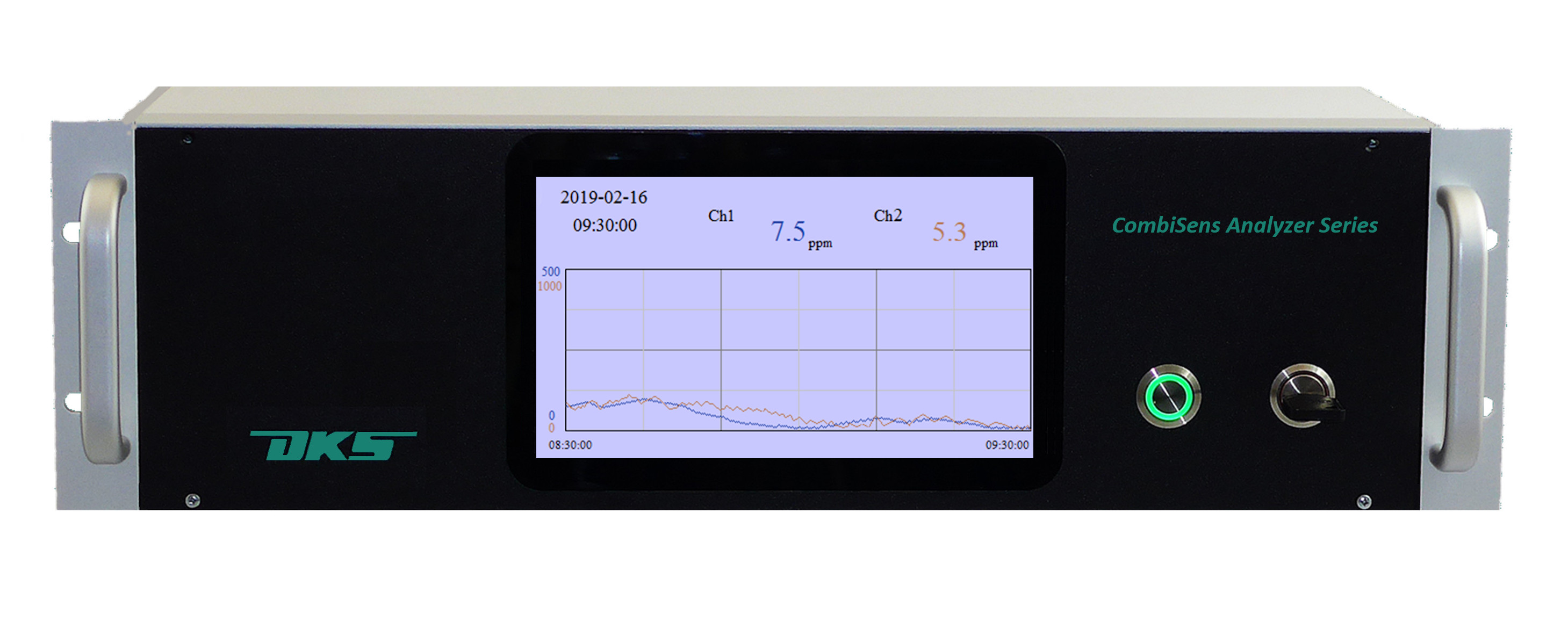

Produktfoto: Beispielbild

Produktfoto: Beispielbild

With our CombiSens Analyzer Series you can solve the following tasks:

- Configuration of an individual multi-parameter gas analyzer

- Free choice of manufacturer-independent measurement principles

- An easy-to-use graphical user interface with a highly sensitive touchscreen for all parameters

- Uniform calibration and adjustment on one device for all parameters

- Optional flow monitoring

- Logging for up to 6,000 alarms

- Expert calibration function (1-point, 2-point, 3-point and n-point calibration / adjustment possible)

- Powerful self-diagnosis function

- Limit relay

- Watchdog

- Powerful control function

- Flexible fieldbus communication functions for IOT4.0

- Optional fieldbus MODBUS, HART, Foundation fieldbus FF, PROFIBUS PA, PROFIBUS DP etc.

Measurement principles already supported:

- Coulometric with P2O5-sensor

- Electrochemical cells

- Capacitive

- TDLS

- potentiometric ZrO2 cell

- NDIR

- WLD / TCD

- NDUV

- and much more

We work with almost all well-known manufacturers of sensors in gas analysis. In principle, almost any transmitter or analyzer can be integrated via a digital or analog interface.

Applications

- ASU (air separation units)

- Chemical & pharmaceutical industry

- Petroleum and petrochemical industries

- Metallurgical processes

- Glass manufacturing

- Semiconductor industry

- Food and beverage industry

- Heat treatment, inert gas monitoring

- Medical applications (e.g. monitoring of medical oxygen)

- Environmental and process gas measurement

- Engine development

- Compressors

Construction options

The example image you can see above shows a 19 "rack (2HU). It is possible to install the measuring sensors directly in the device, which is generally recommended for inert gases. For corrosive and and flammable gases, the sensors are to be installed in a separate analysis cabinet with cabinet flushing We strongly recommend that you contact us about this and together we will find the best solution for you.

Measuring components and measuring ranges

| gas | Selection of measuring ranges (others please inquire) | Measuring principle |

| Ar |

0-3% until 100% |

Thermal conductivity (TCD, TCD), |

| C2H2 |

0 - 500ppm 0-10% |

Laser (TDLS) |

| CH4 |

0-100ppm 0 - 500ppm until 100 % |

Thermal conductivity (TCD, TCD), laser (TDLS) |

| CH6 | 0 -1000ppm, | Laser (TDLS) |

| Cl2 |

0 - 500ppm up to 30% (vol.) |

Thermal conductivity (TCD, TCD), ultraviolet photometry (NDUV) |

| CnHm |

0 - 500ppm until 100 % |

Thermal conductivity (TCD, TCD), infrared photometry (NDIR) |

| CO |

0 - 50 ppm until 100 % |

Thermal conductivity (TCD, TCD), infrared photometry (NDIR) |

| CO2 |

0-3% until 100% 0-500ppm |

Thermal conductivity (TCD, TCD), infrared photometry (NDIR) |

| CO2 |

0-200 ppm up to 100% |

Thermal conductivity (TCD, TCD), infrared photometry (NDIR), laser (TDLS) |

| D2 |

0 - 0.7% until 100% |

Thermal conductivity (TCD, TCD), |

| H2 |

0 - 0.5% until 100% |

Thermal conductivity (TCD, TCD), |

| H2O |

0-20000ppb 0-2000ppm 0-500ppm up to 30% |

Coulometric measurement (P2O5), TDLS |

| H2S |

0-100ppm up to 5,000ppm |

Thermal conductivity (TCD, TCD), ultraviolet photometry (NDUV) |

| HCl |

0 - 50ppm 0 -100ppm |

Laser (TDLS) |

| Hey |

0 - 0.8% until 100% |

Thermal conductivity (TCD, TCD), |

| Kr |

0 - 2% until 100 % |

Thermal conductivity (TCD, TCD), |

| Extinguishing gas (R125) |

0 - 5% until 100 % |

Thermal conductivity (TCD, TCD), |

| N2 |

0-3% until 100% |

Thermal conductivity (TCD, TCD), |

| N2O |

0 - 500ppm until 100 % |

Thermal conductivity (TCD, TCD), infrared photometry (NDIR) |

| No |

0 - 1.5% until 100 % |

Thermal conductivity (TCD, TCD), |

| NH3 |

0-15ppm 0 - 50ppm |

Laser (TDLS) |

| NO |

0-300ppm up to 5,000ppm |

Thermal conductivity (TCD, TCD), ultraviolet photometry (NDUV) |

| NO2 |

0 - 50 ppm up to 5,000 ppm or 0% - 5% until 100% |

Thermal conductivity (TCD, TCD), ultraviolet photometry (NDUV) |

| O2 |

0-100% 0 - 25% 0 - 10,000ppm 0-10ppm 0-100ppm 0 - 1000ppm |

Potentiometric ZrO2, paramagnetic, electrochemical |

| O3 |

0-10 ppm up to 5,000 ppm |

Thermal conductivity (TCD, TCD), ultraviolet photometry (NDUV) |

| SF6 |

0 - 2% until 100 % |

Thermal conductivity (TCD, TCD), |

| SO2 |

0 - 50ppm up to 10 % |

Thermal conductivity (TCD, TCD), ultraviolet photometry (NDUV) |

| Other gases: | on request |

technical data

|

Diagnostic function |

Flow monitoring, self-diagnosis of sensor and controller, heartbeat monitoring |

|

Alarm logger |

Internal flash memory, up to 6000 alarms |

|

Analog output |

4-20mA, maximum load 500Ω (galvanically separated) |

|

Relay output |

Relay (2A, 230V AC), system alarm, galvanically separated |

|

Control function |

Optional timer controller, PID analog controller, PWM controller |

|

Calibration / adjustment |

Expert calibration function, multi-point calibration function up to 9 points |

|

communication |

RS485 MODBUS RTU, HART, Foundation Fieldbus FF, PROFIBUS PA, PROFIBUS DP, MODBUS TCP / IP, etc. |

|

power |

80 ~ 264V AC, 1A or 19 ~ 28V DC, 3A |

|

Electrical protection |

EMI / RFI CEI-EN55011 - 05/99 |

|

Ambient temperature |

-15 ~ 60 ° C |

|

Storage and transport temperature |

-25 ~ 70 ° C |